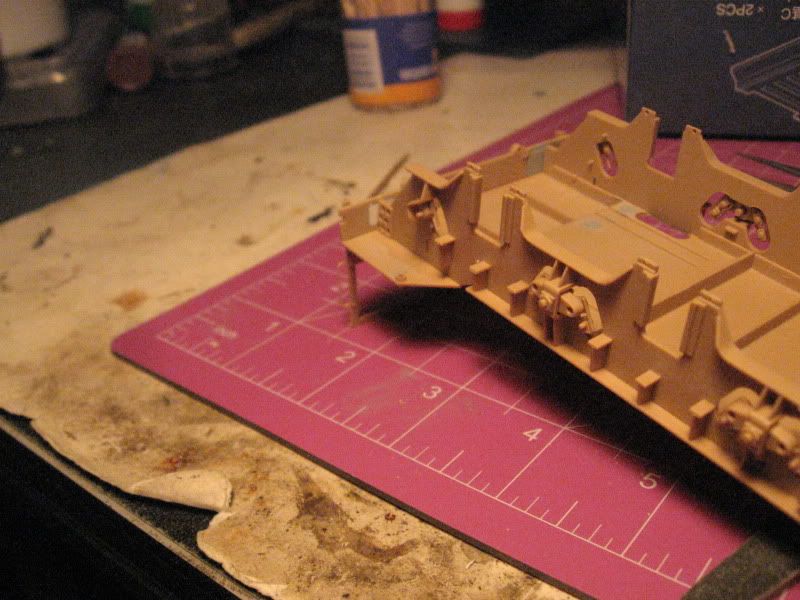

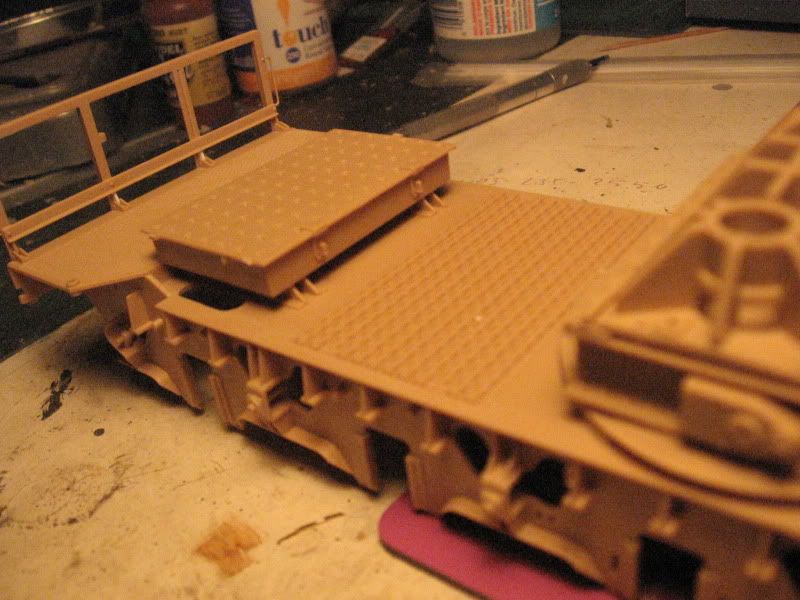

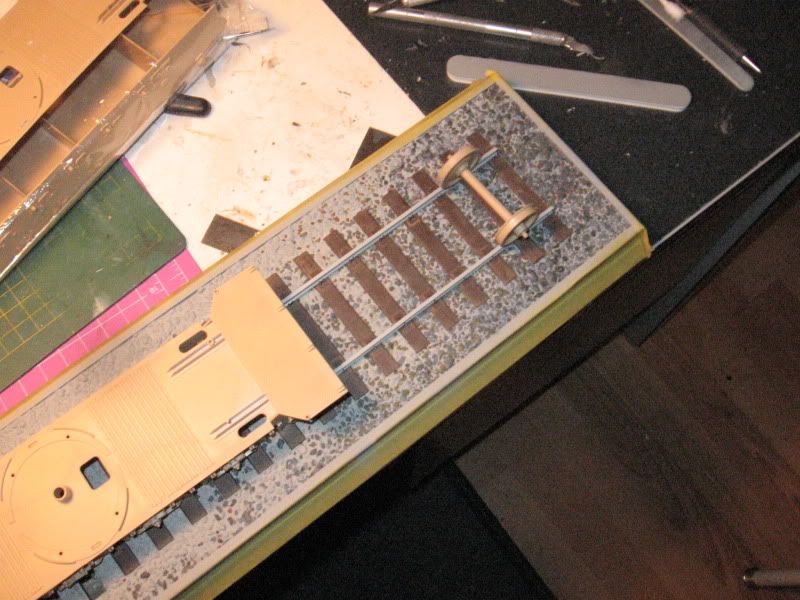

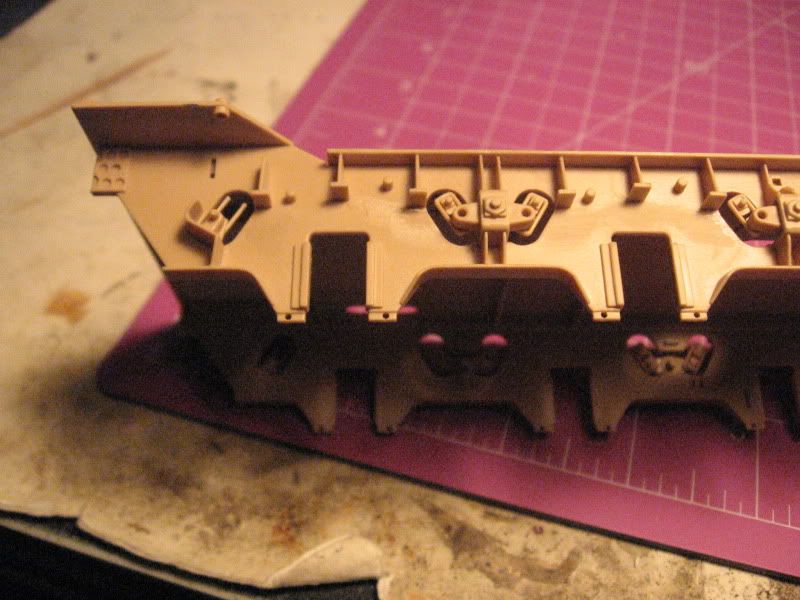

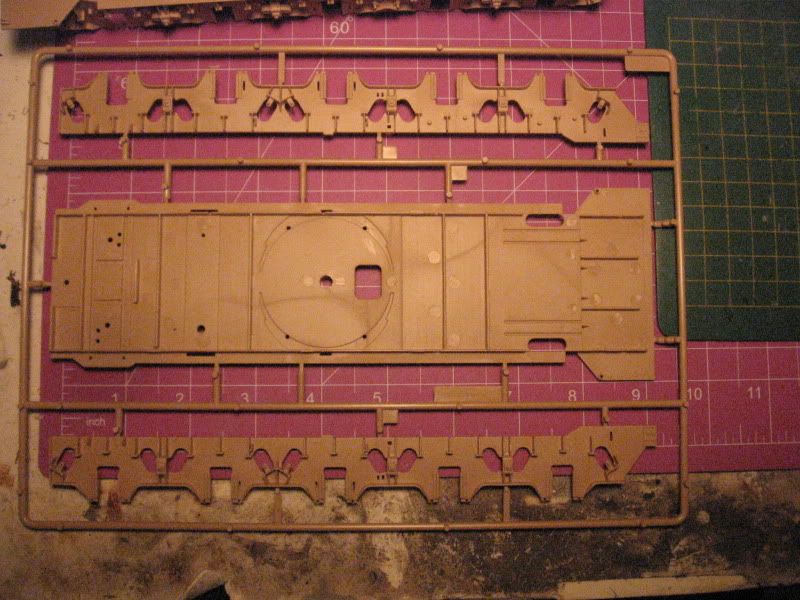

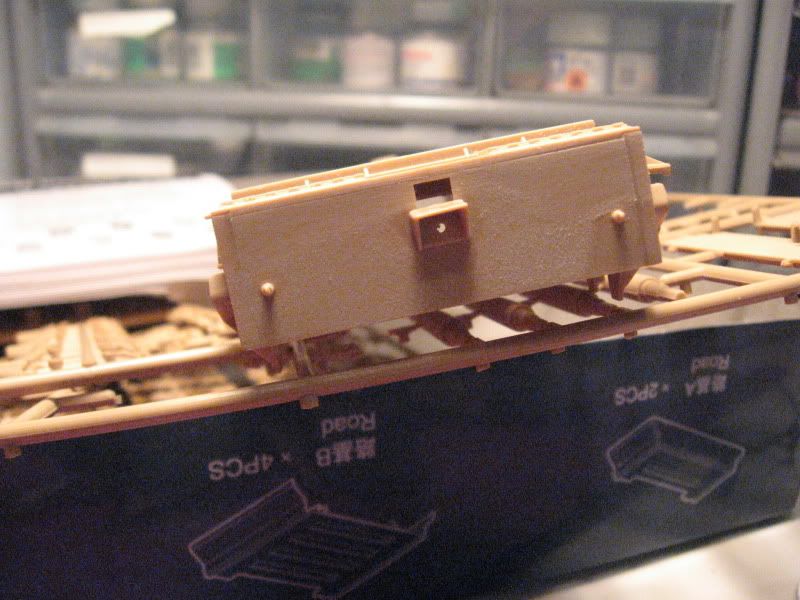

So I decided to go ahead and start the on the trucks. There is a front and rear assembly, but there are only 2 things different, being the mounting bracket for the bar which is used to keep these units together when the Mortar is not being carried, and a cover on the top plate. Now Trumpeter would have you assemble all the springs and brake assembles on each side plate before attaching them to the top, Givin the amount of delicate pieces involved and some piant coverage issues I don't think this is the best plan, so I after looking things over it is obvious that one can assemble the side and end plates to the top and add all the fiddly bits later. On the first car I did add all the inside bits, of course I broke a few, on the second one I'm just going to do them later.

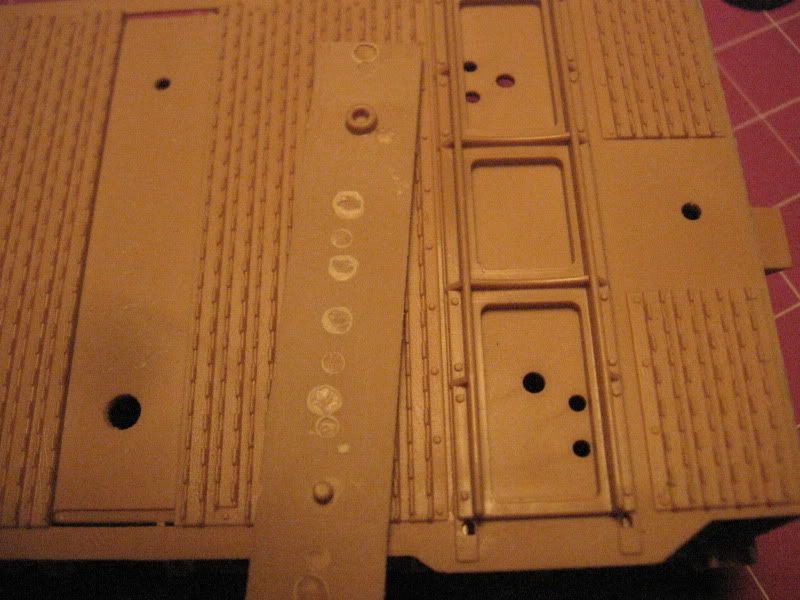

There is a fair amount of clean up involved in these parts from mold seem and ejector pins

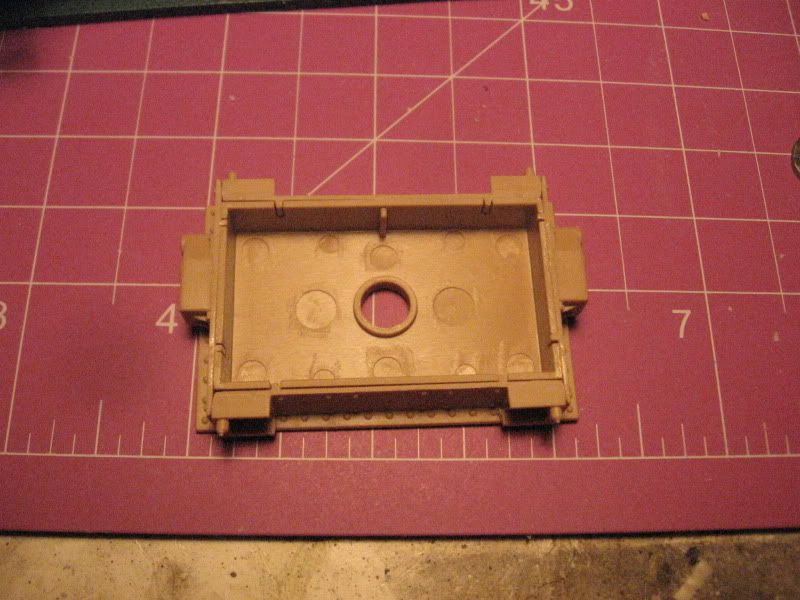

I decided the best place to start is the mounting bracket for the bar, as this requires to ole to be punched in one of the sides,part A-3, and part G-3 glued in. Trumpeter would have you do this later on, but if one wants to be sure any gaps can be filled that is not a good idea.

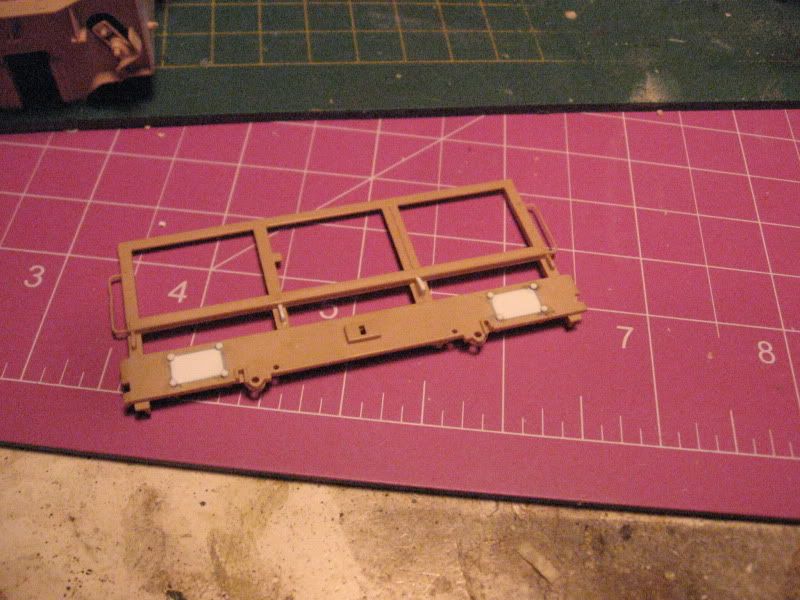

Next it's a good idea to install Parts G-4 and 5.

If you don't you will have a bit of an indent where the side attach to the top which is a bit difficult to fill in if you want a smooth join. Of course I forgot to do this on the first set.

These are a very tight fit requiring a slight amount cleaned off of each end for them to pop into place, the mating surface on these parts is very ruff looknig like someone gouged out the upper plate around the ejector pins, so there is a bit of scraping involved i getting them to sit flat.

But once they are in place the look good and although there is a tiny gap, this should hardly be noticable once everything is painted.

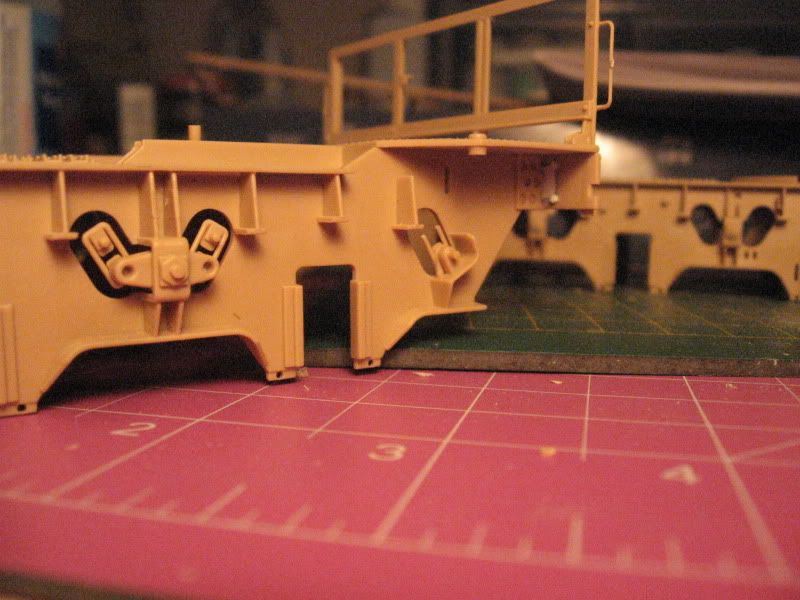

Everything fits together well once the parts are cleaned up, for all the suspension pieces the fit is a bit sloppy but this is not a bad thing as there is quit bit of leeway when it comes to lining things up and the axles don't need to be glued to the springs so getting things to line up and sit flat won't be a problem. The lip that the sides and end butts up agianst is slightly beveled so it's just a matter of butting the side agianst the bottom of the lip and keeping the ribs flat to the mating surface and all will be square.

The lip the end piece butts up to is also beveled a bit and needs to be shaved down to get a flush fit. I think that this part was a single flat piece wich was welded on the end on the real thing so I'm going to fill in all the seems.